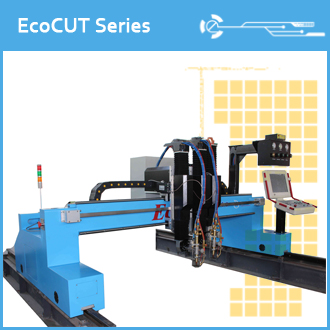

The EcoCUT CNC plasma / flame cutting machine is developed to deliver High Performance and Quality while maintaining considerable economical efficiency.

Widely used in various fields of metal processing such as: sheet processing, bridge engineering, steel structure engineering, marine engineering, packaging, chemical agricultural machinery industry etc.

Basic Features :

| No. | Parameters | Unit | EcoCUT Machine Model |

||||||

| EC30 | EC35 | EC40 | EC45 | EC50 | EC55 | EC60 | |||

| 01 | Frame-driven Mode | -- | Bilateral Drive | ||||||

| Unilateral Drive | |||||||||

| 02 | longitudinal rail center distance (W) | mm | 3000 | 3500 | 4000 | 4500 | 5000 | 5500 | 6000 |

| 03 | Longitudinal rail length (L) | mm | Based to customer requirements | ||||||

| 04 | Single Torch Effective Cutting Range (a) | mm | (W-700) x (L-3000) (Range with operation console) | ||||||

| 05 | Dimension (A) | mm | Length, Width, Height (W+500) x 1800 x 1960 | ||||||

| 06 | Cutting Precision Standards | mm | QK Standard Q/320583-KJQK-001-2009 | ||||||

| 07 | Machine Free Running Speed | mm | 15m / min | ||||||

| 08 | Machine Drive Power | W | 2200 | ||||||

| 09 | Input Power | VCA | 220VCA/50Hz | ||||||

| 10 | Flame Cutting Depth | mm | 6 - 120mm | ||||||

| 11 | Flame Cutting Gas | -- | Oxygen/Acetylene, Propane, Natural Gas | ||||||

| 12 | Torch Quantity | -- | Standard matching 2 torches, Optional matching 2-6 torches | ||||||

| 13 | Torch Lifter | PCS | Q250C/Flame, Q250E/Plasma | ||||||

| 14 | Ground Beam Number | -- | 200x300mm H steel, rail installation mode based on customer requirements | ||||||

| 15 | longitudinal Rail | -- | 30KG transverse rail | ||||||

| 16 | Cutting Platform | -- | Dry / Water Bed / Dust ventilation cutting platform | ||||||

| 17 | Platform | -- | Based on customer requirements | ||||||

| 18 | Operation Console | -- | SmartPlus, Q-Panel Console | ||||||

The MiniCUT CNC plasma / flame cutting machine is cost-effective solution specially developed for small quantity cutting and space-challenged environments. Compact in design, the MiniCUT makes no compromise in delivering precision and high-speed performance - Ideal for almost any plate & sheet-metal cutting industry.

Basic Features :

| No. | Parameters | Unit | MiniCUT

model: |

MiniCUT

model: MIN21 |

MiniCUT

model: MIN26 |

| 01 | Longitudinal rail centric distance (W) | mm | 1850 | 2100 | 2600 |

| 02 | longitudinal rail length (L) | mm | Based on customer requirements (recommendation up to 10 M) | ||

| 03 | Machine Width (A) | mm | 2090 | 2340 | 2840 |

| 04 | Machine Length (B) | mm | 900 | ||

| 05 | Machine Height (H) | mm | 1800 | ||

| 06 | Effective Cutting Width (a) | mm | 1250 | 1500 | 2000 |

| 07 | Effective Cutting Length (b) | mm | L-1500 | ||

| 08 | Accuracy Standards | -- | QK Standard Q/320583-KJQK-001-2009 | ||

| 09 | Repeatability Accuracy | mm | 0.20 | ||

| 10 | Longitudinal & Transverse Accuracy | mm | 0.15mm / 10m | ||

| 11 | Diagonal Error | mm | 0.30 | ||

| 12 | Machine Free-running Speed | mm | 15m / min | ||

| 13 | Machine Drive Power | W | 2000 | ||

| 14 | Input Voltage | VCA | 220VCA / 50Hz | ||

| 15 | Drive Mode | -- | AC Servo System: Unilateral drive / Bilateral drive | ||

| 16 | Plasma Parts (Optional) | -- | Depending on customer needs | ||

| 17 | Flame Cutting (Optional) | mm | 6-60mm | ||

| 18 | Ground Beam (Optional) | -- | 200 x 300mm, according to customer requirements | ||

| 19 | Cutting Platform (Optional) | -- | Dry / Water Bed / Dust ventilation cutting platform | ||

| 20 | Lifter | -- | Matching Q300, Q100, Q150A (Optional) | ||

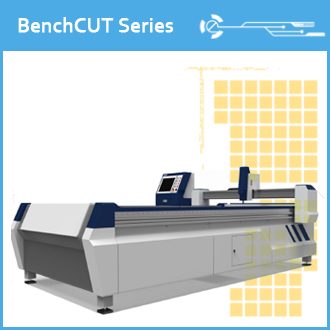

The BenchCUT CNC Plasma cutting machine is a high speed precision table developed to work with high performance plasma systems.

The machine comes fully equipped with a modular fume extraction table (a water table version is also available), and easy to setup. It requires minimal maintenance and is designed to be robust and reliable. Its compact design is especially ideal for space-challenged environments.

Basic Features :

| - Reinforced Gantry Machine with AVC THC Sensor |

| - Longitudinal Drive: AC Servo motor/rack/round linear guide |

| - Transverse Drive: AC Servo motor/rack/round linear guide |

| - Operator Panel Position: Left |

| - Effective Cutting Width: 1500mm |

| - Effective Cutting Length: 3000mm |

| - Machine Width: 2460mm |

| - Machine Length: 2960mm |

| - Machine Height: 1930mm |

| - Cutting Machine Precision: ISO8026-1991 |

| - Cutting quality & size precision: ISO9013-2002 |

| - Machine moving speed: Moving speed u=0-24m/min, Acceleration=50mg |

| - Cutting Capacity: Dependent on Plasma System selection |

| - Overall Accuracy: Reproducibility = (less than or =+ 0.2mm), X,Y Squareness = (less than or =+ 0.2mm) |

| - Hose & Cable for (X, Y axis): power track chain |

| - CNC Power Supply: 2.0kw (only for motor power) |

| - Input Voltage: 220V/50Hz |

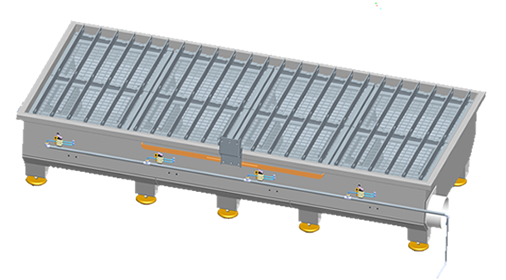

Work Table Selection: |

| 1)

Water Type 2) Fume Extraction Type |

|

| Our Fume Extraction Table is designed with a 'Smart Localized Extraction' (SLE) feature that tracks the position of the Plasma torch and opens the vent in the relevant quadrant to draw the fumes. As the vents in the non-active areas are closed, it maximizes suction and improves extraction rate. |

The Mantis is a solution designed for portability and space-challenged environments, while maintaining the standard functionalities and features of a regular gantry CNC machine.

Light weight and easy to assemble / disassemble, The Mantis is widely used in shipbuilding, automobile, petrochemical, electric power machinery, engineering machinery, mining machinery, pressure vessels etc. in the area of Carbon steel (flame cutting), stainless steel, aluminum (plasma cutting) and other metal plates and materials.

Basic Features :

| Models | HC-1020 | HC-1225 | HC-1530 | HC-1630 |

|---|---|---|---|---|

| Input Power Source | 220±10%V AC 50Hz 220W | |||

| Cutting Mode | 02/C3H3 or C2H2, Plasma available | |||

| Effective Cutting Range | 1000 x 2000 | 1225 x 2500 | 1500 x 3000 | 1600 x 3000 |

| Track L x W x H | 2500 x 273 x 60 | 3000 x 273 x 60 | 3500 x 273 x 60 | 2500 x 273 x 60 |

| Track Holder Quantity | 2[{500(L) x 80(W) x 40(H)}mm] | |||

| Beam Section Size | 50 x 60 mm | |||

| Cutting Speed | 50-2000 (Max 4000mm/min) | |||

| Cutting Thickness(Flame) | 5 - 150mm | |||

| Cutting Thickness(Plasma) | In terms of customer's plasma power source | |||

| Move Precision | Flame, Electric Height Adjustment(±60mm) | |||

| Host Weight | 19kg | |||

| Gas Pressure | Max 1.0Mpa | |||

| Oxygen Pressure | Max 0.7Mpa | |||

| Type of Gas | Propane, Ethyne | |||

| Power down and breakpoint memory. | ||||

| Cutting slot compensation. | ||||

| Preheated time memory. | ||||

| Temperature-controlled fan. | ||||

| 7 inch high-resolution LCD. | ||||

| Chinese/English menu system. | ||||

| Import files from USB drives. | ||||

| Dynamic/static graphic processing display. | ||||

| Adjustable starting speed, acceleration and deceleration time even while moving. | ||||

| Support EIA code (G code) and other types of nesting software such as FastCam. | ||||

| Various processing parameters to meet the needs of different requirements. | ||||

| High-subdivision stepper motor drive. | ||||

| Smooth movement, low noise, high accuracy. | ||||

| Multiple torch holding structure. | ||||

| Standard electric height adjustment. | ||||

| Three-way solenoid valve. | ||||

| Flame cutting protective heat shield. | ||||

| Steel and anti-magnetic outside frame to ensure reliable and stable operation of CNC system. | ||||

| Compatible for various types of plasma cutting machine. | ||||

| Automatic arc voltage adjustment according to THC. | ||||

| ARM+DSP high-speed, high-precision cutting. | ||||

| 45 common graphics gallery. | ||||

| Graphic scale, rotate, mirror, matrix arrangement, steel plate correction. | ||||

| Export files and parameters backup | ||||

| Separately control oxygen gas from plasma IO, two grades preheat, three perforation; plasma arc voltage feedback, position feedback. | ||||

| Automatic limit speed and shutdown of arc voltage while cutting corners. | ||||

PLAMILL has plasma torch head & machining head. PLAMILL is designed to fit all steel fabrication by Accu-one's advanced technology. This machine works Drilliing, Tapping, Milling, Boring, Plasma Cutting at one process. PLAMILL is equipped with various convenient system and easy to operating.

Basic Features :

| PLAMILL 26A | ||||

|---|---|---|---|---|

| Structure | Machine Size | X x Y x Z | 7000 x 16500 x 3500 | |

| Machine Weight | 15ton | |||

| Machine Type | X | High Rigidity Bridge Structure | ||

| Y | LM Base & Hydraulic Clamp Base | |||

| Table | Roller & Ball Caster Base | |||

| Controller | CNC 6 Axis Controll | |||

| Model | TurboTek or Fanuc | |||

| Display | 12.1 inch | |||

| Communication | Network/USB | |||

| Operation | Meterial Clamp | Edge Clamping | Hydraulic Clamp | |

| Max.Speed | X/Y | 20m/min | ||

| Z | 10m/min | |||

| Load Meterial Size | Max.Material Size | X x Y x T | 2450mm x 6300mm x 50T | |

| Min.Meterial Size | X x Y x T | 500mm x 1000mm x 6T | ||

| Max.Weight | 5ton | |||

| Machining | ||||

| Spindle | Output Power | 11kw,2000RPM | ||

| Size | BT40 | |||

| Auto Tool Changer Slot | 8EA | |||

| Max.Drill/Max.Tap | 30mm/M2A | |||

| Plasma | ||||

| Max.Cutting Thick | Piercing | 32mm | ||

| Edge Cutting | 50mm | |||

| Usage Gas | AIR/O2/N2/H17 | Power | ||

| Machine | 3P AC220V 60Hz/10kW | |||

| Plasma Supply | 275AMP | 3P AC380V 60Hz/39kW | ||

| Usage Gas | AIR/O2/N2/H17 | |||

| Hydraulic Pump | 3P AC220V 60Hz/5.5kW | |||

| Fume Collector | 3P AC380V 60Hz/7.5kW | |||

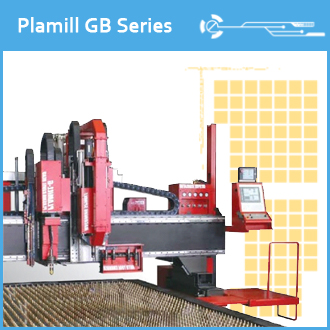

PLAMILL GB is CNC machining and bevel plasma combined machine. This machine works Drilliing, Tapping, Milling, Boring, Plasma Cutting at one process. PLAMILL GB is equipped with various convenient system and easy to operating.

Basic Features :

| MODEL | PLAMILL G | |||

|---|---|---|---|---|

| Machine | Gantry Size | X x Y x Z | 7000 x 3000 x 3500 | |

| Machine Weight | 6ton | |||

| Machine Type | X | Rigidity Bridge Structure | ||

| Y | 50Kg Rail | |||

| Table | Grating & Copper Pin | |||

| CNC | ||||

| Model | B&R | |||

| Display | 15 inch/1024*768 | |||

| I/O | 192/128 | |||

| Motion Control | Ethernet/PowerLink | |||

| Communication | Network/USB | |||

| Meterial Clamp | Clamping | Manual Angle Side Clamp | ||

| Manual Grating Clamp | ||||

| Traverse Speed | X/Y | 20m/min | ||

| Z | 20m/min | |||

| Repeatability | 0.05m/min | |||

| Servo Motor | X | Max.4.0Kw * 1EA | ||

| Y1/Y2 | Max.4.0kW * 2EA | |||

| Power | 3P 220v 60Hz 50kW | Available Cutting Size | Thickness | Machining | 50mm |

| Plasma | 50mm | |||

| Oxyfuel | 100mm | |||

| Width | W | 3300mm | ||

| Length | L | Depend on table | ||

| Machining Chip Suction | ||||

| Power | 15kW Cyclone | |||

| Function | Suction & Seperate (Chip & Cutting Oil) | |||