Developed to deliver performance, and quality while maintaining considerable economical efficiency.

Read More

A cost-effective solution specially developed for small quantity cutting and space-challenged environments.

Read More

Its modular structure is designed to enable fast setup, and ideal for space-challenged environments.

Read More

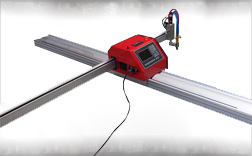

Its solution designed for portability and space-challenged environments, while maintaining the standard functionalities.

Read More

PLAMIL is designed to fit all steel fabrication by accu-one's adavanced technology.

Read More

PLAMIL GB is designed to fit all high precise plasma cutting & machining at one process.

Read More| CAD function | Full compatibility |

| Standard Part Library | True Shape Nest |

| User Report Sheet | Manual Nest |

| NC simulation | Auto Nest |

If there is a problem with machine operation, Immediate technical support is made possible by best remote-control program. the technical support team in the head office and the machine operator can easily solve the problem in watching the same screen.

Know More!Vyoncut Machinery was formed and made possible by a competitive team of Engineers with experience in metal fabrication sectors unlike most of the distributors and hence understanding the requirements of the customers. We have a competitive team of electrical and mechanical engineers in providing after sales services and retrofitting of the existing machines.

Our vision is to be the world’s leading brand and we’ve set out to achieve that by constantly challenging ourselves in the area of innovation and quality to meet our customers’ needs.

We have our own in-house Research & Development lab run by a team consisting of top-notch engineers and specialists, all dedicated to exploring new technologies and constantly re-looking at how to improve existing designs through vigorous testing and customer feedback.

Our R&D team was responsible for the development of various patented components such as Q-Panel, SmartNC, Q250 Lifter, Rail and Transverse Guide, and perfecting our 3D Beveling system. This team was also responsible for the development of our quality products such as the MiniCUT, EcoCUT, SmartCUT, and MaxCUT that are widely used today.